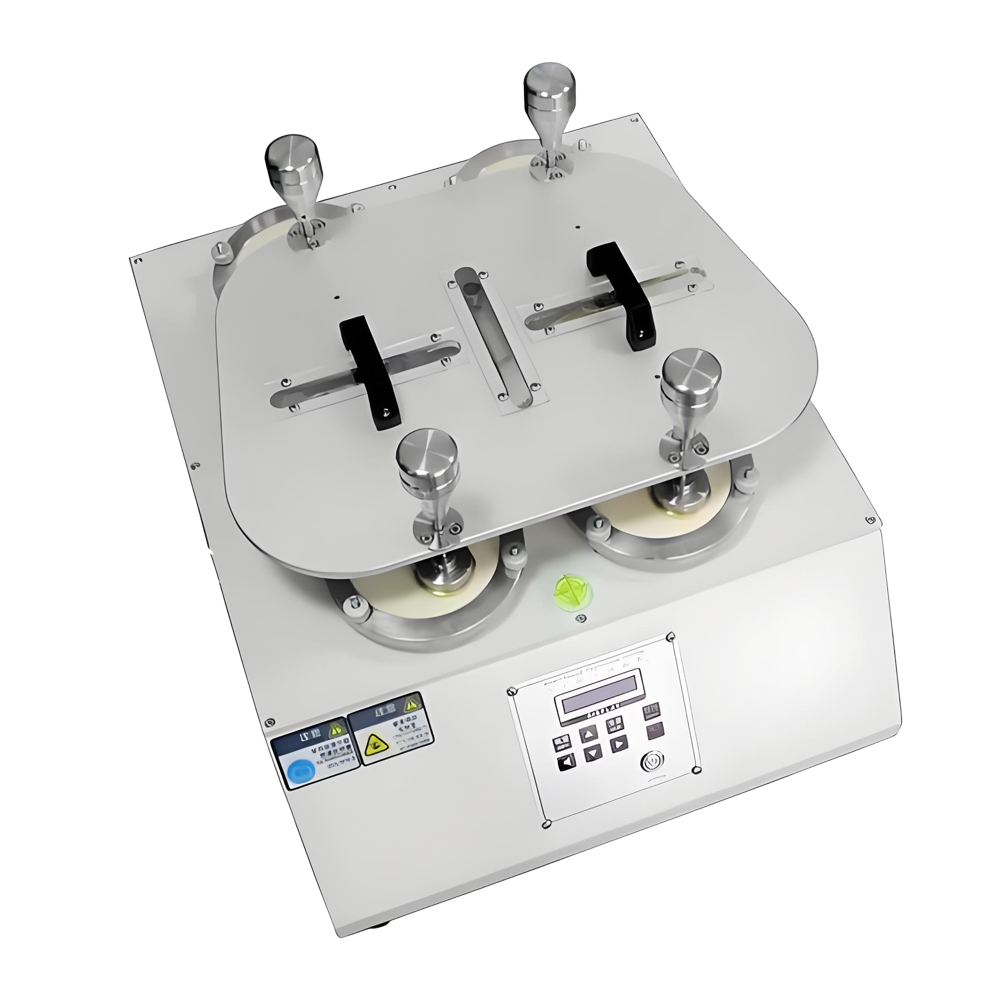

martindale fabric tester

138005.0 INR/Unit

Product Details:

- Response Time Immediate (operates in real-time)

- Power Supply AC 220V, 50Hz

- Automation Grade Semi-automatic to fully automatic (model specific)

- Port Size Standard testing ports (8 or 12 depending on model)

- Test Range Up to 999,999 cycles

- Max Height Approx. 450 mm (machine overall)

- Specimen Size Diameter 38 mm (for abrasion), 140 mm (for pilling)

- Click to view more

X

martindale fabric tester Price And Quantity

- 1 Unit

- 138005.0 INR/Unit

- Precision geared motor

- Minimal maintenance

- Conforms to ISO 12947, ASTM D4970

- 670 mm × 530 mm × 300 mm

- Up to 99 hours, 59 minutes

- Emergency stop, overload protection

- Powder-coated steel construction

martindale fabric tester Product Specifications

- AC 220V, 50Hz

- Lab testing of abrasion & pilling resistance

- Immediate (operates in real-time)

- Customizable as per specimen

- Standard testing ports (8 or 12 depending on model)

- 47.52 rpm

- Semi-automatic to fully automatic (model specific)

- Approximately 85 kg

- Up to 999,999 cycles

- Approx. 450 mm (machine overall)

- Diameter 38 mm (for abrasion), 140 mm (for pilling)

- 60.5 mm (standard), 24 mm (optional)

- Digital LED/LCD screen

- 50 Hz

- Up to 8 or 12 (model dependent)

- 1 cycle

- 15C - 35C (Recommended operating environment)

- Bench-top

- Multi-station (8 or 12 specimens/batches)

- Programmable cycles, multiple test heads, easy specimen mounting, automatic stop

- Standard abradant supplied

- 20%-65% RH (Recommended test environment)

- Digital control with touch screen interface

- User-friendly touch panel

- 0 - 999,999 cycles

- 220V 10%, 50Hz

- 1 cycle

- Textile, leather, and fabric abrasion and pilling tests

- Precision geared motor

- Minimal maintenance

- Conforms to ISO 12947, ASTM D4970

- 670 mm × 530 mm × 300 mm

- Up to 99 hours, 59 minutes

- Emergency stop, overload protection

- Powder-coated steel construction

martindale fabric tester Trade Information

- Cash in Advance (CID)

- 90 Unit Per Month

- 7 Days

- All India

Product Description

martindale fabric tester Technical parameters:

| Model | DR-J803-1 Martindale Abrasion Tester |

| Station number | 4 station , 6 station , 8 station , 9 station (custom) |

| Count display | a. Estimated counting:0~999999 times |

| b. Total counting:0~999999 times | |

| Maximum dynamic range | 240.5mm ,60.50.5mm |

| Weight of pressure thing | a.Gripper:2001g |

| b. Cloth samples hammer:3952g | |

| c. Furniture accessories sample hammer:5942g | |

| d. Stainless steel butterfly piece:2601g | |

| Effective friction diameter of grinding block | A type: 200g (1.96N) friction head 28.8-0.084mm |

| B type: 155g (1.52N) friction head 90-0.10mm | |

| The relative velocity of Gripper and the grinding station | 50-2r/min |

| Weight of pressure hammer | 238510g |

| Dimensions | 885mm600mm410mm(LWH) |

| Weight | 150kg |

| Power | Ac220V,50Hz |

The Martindale Fabric Tester is a device specifically designed to evaluate the wear resistance of textiles. It tests the durability and service life of fabrics by simulating the friction and wear that they may encounter during actual use. Here are some detailed information about the Martindale fabric tester:

Functional Features

1. Simulate actual wear: The tester simulates the wear of the fabric during wear or use by repeatedly rubbing the surface of the sample.

2. Wide applicability: Suitable for various types of textiles, including fabrics, fabrics, carpets, etc.

3. Adjustable parameters: Users can adjust the load and friction speed as needed to adapt to different testing standards and material characteristics.

4. Standardized testing: Follow international standards for testing to ensure the accuracy and comparability of results.

5. Easy to operate: It has a user-friendly interface, automated testing process, and facilitates data recording and analysis.

component

1. Friction disc and friction block: One of the core components, the friction block contacts the surface of the sample and generates wear through friction.

2. Loading device: used to apply different loads and simulate different degrees of wear.

3. Rotating mechanism: Ensure that the rotational motion of the friction disc has good repeatability and stability.

4. Sample clamping device: Fix the sample to prevent displacement during the testing process.

5. Counter and data recording system: records friction frequency and other important data, and some devices also have data analysis functions.

Usage

1. Fix the fabric sample to be tested on the tester.

2. Select the appropriate load and friction speed according to the testing standards.

3. Start the tester and let the friction block rub against the surface of the sample a predetermined number of times.

4. Observe and record the wear of the sample, including material loss and surface damage.

5. Analyze the test results and evaluate the wear resistance of the fabric.

application area

The Martindale fabric tester is widely used in the research and development, production, and quality control of textiles, especially in the fields of clothing, home textiles, automotive interiors, and more.

precautions

Before conducting testing, ensure that the sample has been pre treated according to the standard.

Use standard friction blocks and ensure their cleanliness and appropriate moisture level.

Follow the corresponding international or national standards for testing to ensure the validity of the results.

Regularly calibrate and maintain the tester to maintain its accuracy and reliability.

By using the Martindale fabric tester, textile manufacturers and researchers can better understand the wear resistance of their products, thereby optimizing product design and improving product quality.

Comprehensive Fabric Testing Solution

Designed for rigorous laboratory analysis, the Martindale Fabric Tester performs abrasion and pilling evaluations as per international standards. Featuring multi-station operation, customizable specimen sizes, and programmable controls, it enables precise, repeatable results ideal for quality assurance in the textile industry.

User-Friendly and Safe Operation

With its digital control system and touch screen operation, this tester offers immediate response and real-time monitoring. Safety features such as an emergency stop and overload protection ensure secure operation during intensive testing, making it suitable for continuous laboratory use.

Reliable Construction and Low Maintenance

The powder-coated steel construction provides excellent durability and corrosion resistance. Designed to require minimal maintenance, this Martindale Tester supports uninterrupted usage, enabling high throughput for manufacturers and suppliers. Its compact bench-top design further enhances usability in diverse laboratory environments.

FAQs of martindale fabric tester:

Q: How does the Martindale Fabric Tester evaluate abrasion and pilling resistance?

A: The Martindale Fabric Tester evaluates the abrasion and pilling resistance of fabrics by subjecting test specimens to controlled, repetitive rubbing cycles against standard abrasive materials. The process simulates real-life wear, measuring how many cycles a fabric endures before showing signs of wear or pilling, all conforming to ISO 12947 and ASTM D4970 methods.Q: What types of materials can be tested with this machine and how many specimens can it handle at once?

A: This tester is suitable for evaluating a wide range of textiles, leather, and fabric samples. Depending on the model, it can simultaneously accommodate either 8 or 12 specimens, making it ideal for batch testing and comparative analysis in quality control settings.Q: When should I use the programmable cycles and timer range features?

A: Programmable cycles and the extensive timer range (up to 99 hours, 59 minutes) are particularly useful when conducting long-duration tests or comparing multiple materials under identical conditions. These features help standardize test protocols and ensure consistent results across different specimens and batches.Q: Where is the best place to operate the Martindale Fabric Tester for optimal results?

A: For best performance and accuracy, operate the tester in a controlled laboratory environment with ambient temperature between 15C and 35C and relative humidity from 20% to 65%. Position the bench-top unit on a stable surface to minimize vibrations and ensure uniform testing conditions.Q: What is the process for mounting specimens on the machine and starting a test?

A: Specimens are mounted using easy-fit holders designed for either 38 mm (abrasion) or 140 mm (pilling) samples. After placement, select the desired test program via the digital touch panel, enter cycle or time settings, and start the test. The tester will operate in real time, providing immediate digital readouts and automatically stopping at pre-set endpoints.Q: How much maintenance does the tester require, and what safety measures are included?

A: The Martindale Tester is engineered for minimal maintenance thanks to its robust, powder-coated steel body and precision drive system. Safety features such as an emergency stop button and overload protection ensure user security during operation. Routine cleaning and occasional checking of mechanisms are generally sufficient for ongoing reliability.Q: What are the main benefits of using this Martindale Tester for exporters and manufacturers?

A: Key benefits include compliance with international standards, high test accuracy (1 cycle), real-time digital monitoring, and the ability to test multiple specimens simultaneously. This enables exporters, manufacturers, and suppliers to efficiently ensure that their textiles meet global quality benchmarks, streamlining quality assurance processes for domestic and international markets.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese