3-Axis Vibration Test Chamber for Electronics

138005.0 INR/Unit

Product Details:

- Application Testing & Measurement

- Power Supply Electric

- Product Type 3-Axis Vibration Test Chamber

- Usage Industrial

- Mounting Type Free Stand

- Material Mild Steel

- Control Mode Manual

- Click to view more

X

3-Axis Vibration Test Chamber for Electronics Price And Quantity

- 1 Unit

- 138005.0 INR/Unit

3-Axis Vibration Test Chamber for Electronics Product Specifications

- Mild Steel

- Free Stand

- 3-Axis Vibration Test Chamber

- Manual

- Industrial

- Electric

- Testing & Measurement

3-Axis Vibration Test Chamber for Electronics Trade Information

- Cash in Advance (CID)

- 80 Unit Per Month

- 3 Days

- All India

Product Description

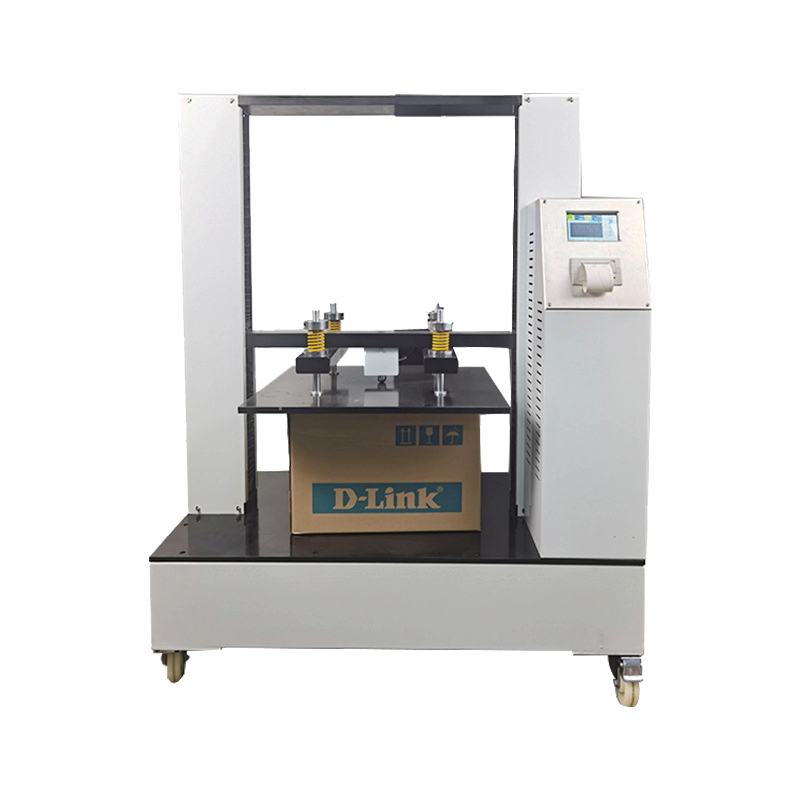

In the electronics industry, ensuring the reliability and durability of products is paramount. The 3-Axis Vibration Test Chamber is a specialized piece of equipment designed to simulate real-world vibration conditions that electronic devices may encounter during transportation, handling, and everyday use. This comprehensive overview will explore the features, functionalities, applications, and benefits of using a 3-Axis Vibration Test Chamber for testing electronic components and devices.

Key Features and Functionalities

1.

2.

3.

4.

5.

Applications and Benefits

The 3-Axis Vibration Test Chamber is widely used in the electronics industry for testing the reliability and durability of various components and devices. Some of the key applications and benefits include:

- Component Testing:

Testing individual electronic components, such as capacitors, resistors, and integrated circuits, to ensure they can withstand vibrations encountered during transportation and handling. - Product Qualification:

Conducting vibration tests on finished products, such as smartphones, laptops, and other consumer electronics, to ensure they meet industry standards and customer expectations for durability and reliability. - Quality Assurance:

Implementing vibration testing as part of a comprehensive quality assurance program to identify and address potential issues early in the product development process. This helps reduce the risk of product failures and improves overall product quality. - Research and Development:

Using the test chamber to evaluate the performance of new materials and designs under vibration stress. This can lead to the development of more robust and reliable products.

Installation and Usage Precautions

To ensure the safe and effective operation of the 3-Axis Vibration Test Chamber, consider the following precautions:

- Proper Installation:

Ensure that the chamber is installed on a stable and level surface to prevent any unwanted movement during testing. The installation area should be well-ventilated and free from external vibrations that could affect test results. - Regular Maintenance:

Perform regular maintenance checks, including inspecting the vibration actuators, verifying the calibration of sensors, and checking the condition of the control system. This ensures that the chamber remains in good working condition and provides accurate test results. - Safety Protocols:

Follow all safety protocols when operating the chamber, including wearing appropriate protective gear and adhering to the manufacturer's guidelines for handling and securing test items. - Training:

Provide adequate training for all users of the chamber. This ensures that they understand how to operate the equipment safely and effectively, reducing the risk of accidents and ensuring reliable test results. -

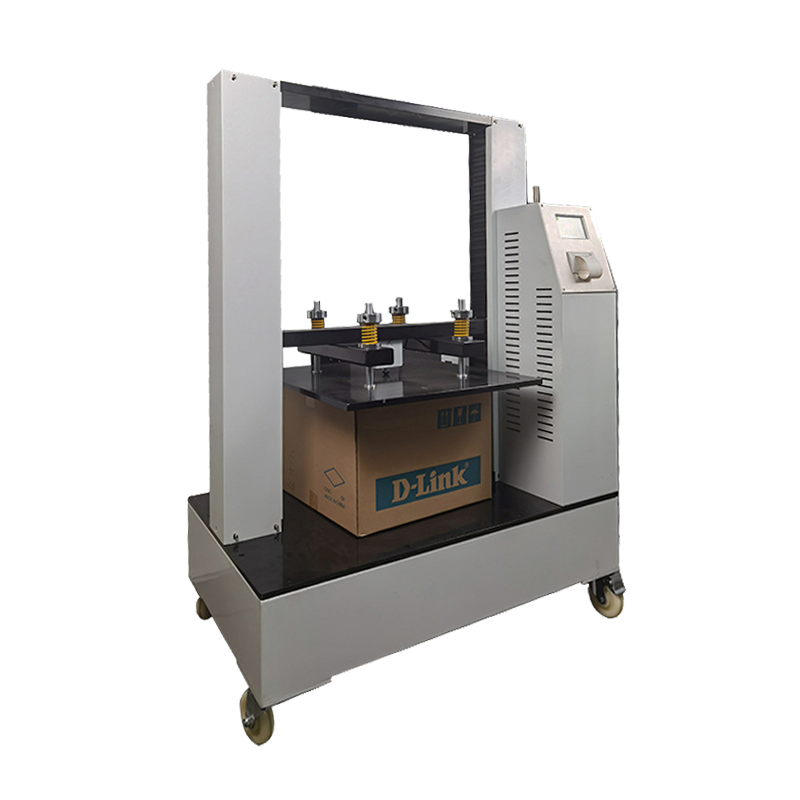

Item DR-B216 Max. Test Load 100kg Frequency Range 60-300rpm Amplitude Range 25.4mm (1 inch) Simulation Speed 25~40km/h Vibration Mode Roundtrip Work Table Size 1000*1200 mm ( L*W, can be customized ) Outside dimension ( L*W*H ) 1255*1070*660mm Speed Mode DC converter or AC Frequency Control Power Capacity 1 HP Weight 150kg Power 220V, 50 Hz Speed Mode DC converter or AC Frequency Control Environmental Conditions Temperature: 5~40C; Related Humidity <85%

Optimal Electronics Testing Solution

The 3-Axis Vibration Test Chamber offers a comprehensive platform for evaluating how electronic products withstand dynamic stress. Its triple-axis functionality ensures simulations closely mimic actual conditions, allowing for accurate performance analysis. Industries can reliably assess the robustness of their devices under varying vibration frequencies, enhancing quality assurance procedures prior to market release.

Built to Last with Mild Steel Construction

Engineered with mild steel, this test chamber withstands heavy-duty use and maintains structural integrity over long testing periods. The material's strength and resistance to corrosion make it particularly advantageous for demanding industrial environments, supporting uninterrupted operation throughout its service life.

FAQ's of 3-Axis Vibration Test Chamber for Electronics:

Q: How does the 3-Axis Vibration Test Chamber improve electronic product reliability?

A: By simulating real-world vibration scenarios across three axes, the chamber uncovers design vulnerabilities in electronic components. This enables manufacturers to refine and strengthen products, ensuring improved reliability when subjected to mechanical stress during actual use.Q: What applications is the 3-Axis Vibration Test Chamber best suited for?

A: This test chamber is ideally used for testing and measurement tasks in the electronics industry, specifically for evaluating the durability and performance of components in industrial settings before final deployment.Q: When should an electronic device undergo vibration testing in this chamber?

A: Vibration testing should be conducted during the product development phase, prior to commercial launch, or when modifying existing designs. This helps identify and address potential weaknesses early in the process.Q: Where is the 3-Axis Vibration Test Chamber typically installed?

A: Owing to its free-standing design, the chamber can be placed in versatile locations within industrial facilities, such as quality control labs or manufacturing environments, where robust product testing is essential.Q: What is the process for performing a test using this chamber?

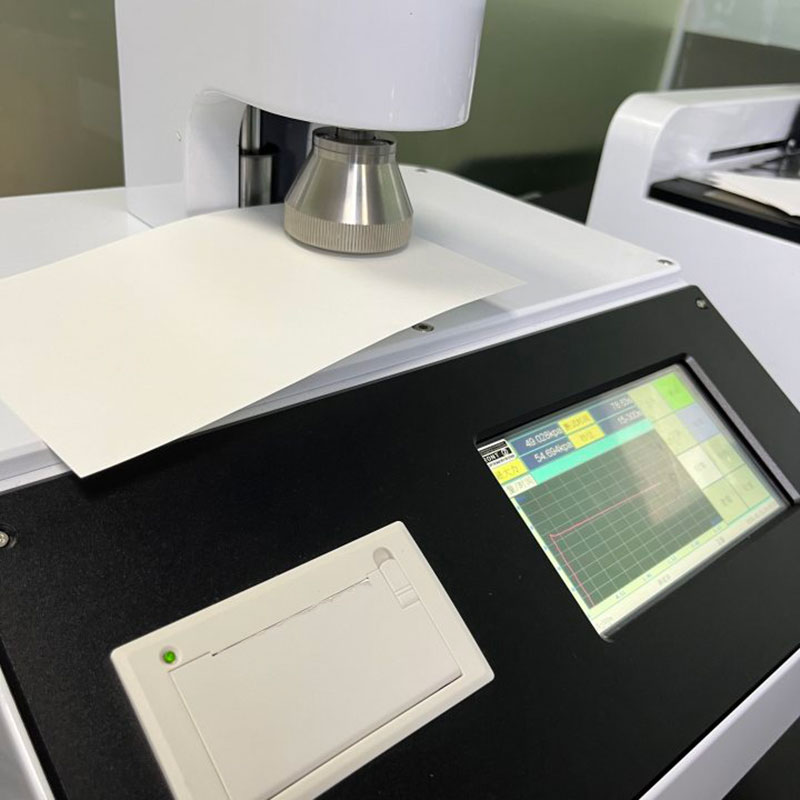

A: The process involves manually setting the desired vibration parameters, placing the electronic device on the chamber's testing platform, and initiating the vibration sequence. The equipment then monitors how the device responds under controlled stress.Q: How is the power supplied to the chamber, and what type of controls does it use?

A: The chamber operates with electric power and features manual control mode, allowing operators to make precise adjustments to testing parameters and tailor each test to particular requirements.Q: What are the benefits of sourcing this chamber from a Chinese exporter, manufacturer, or supplier?

A: Chinese suppliers often offer competitive pricing, rapid production timelines, and robust after-sales support, making them a preferred choice for international businesses seeking reliable and cost-effective vibration testing equipment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese