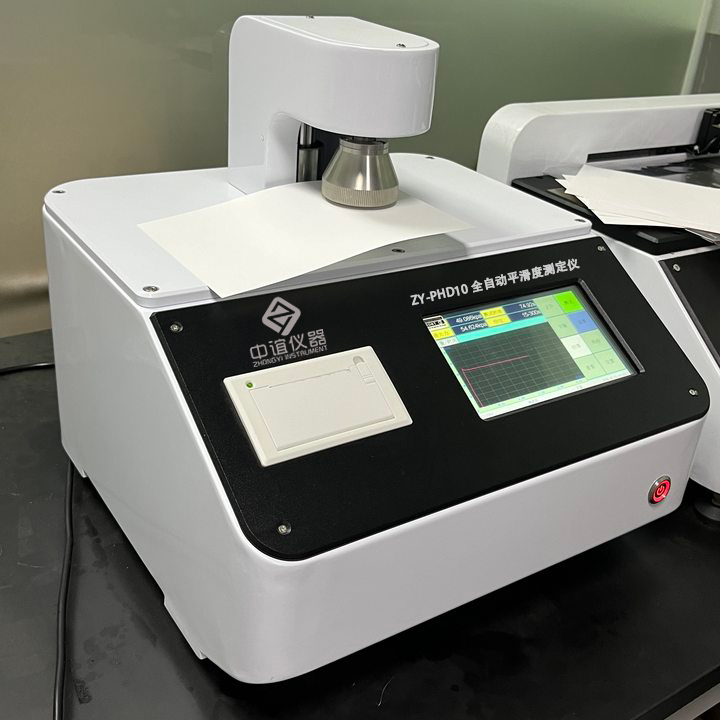

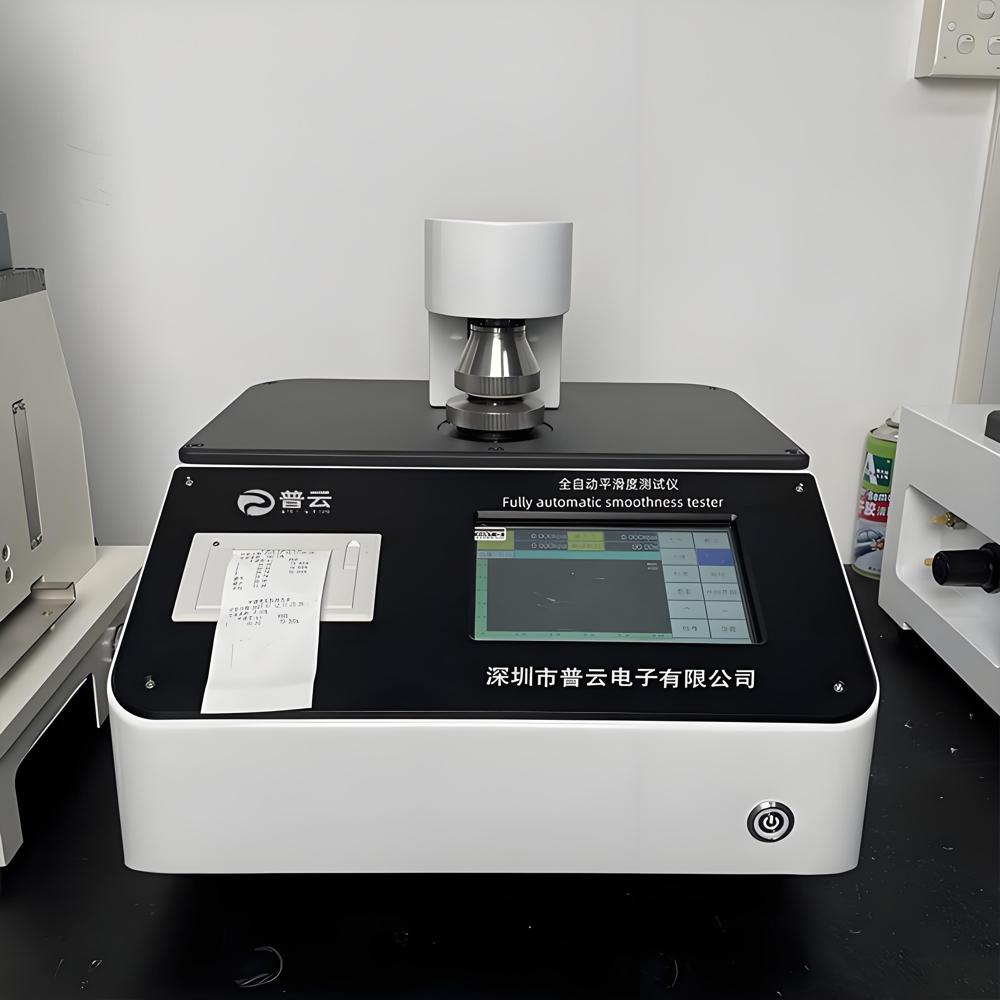

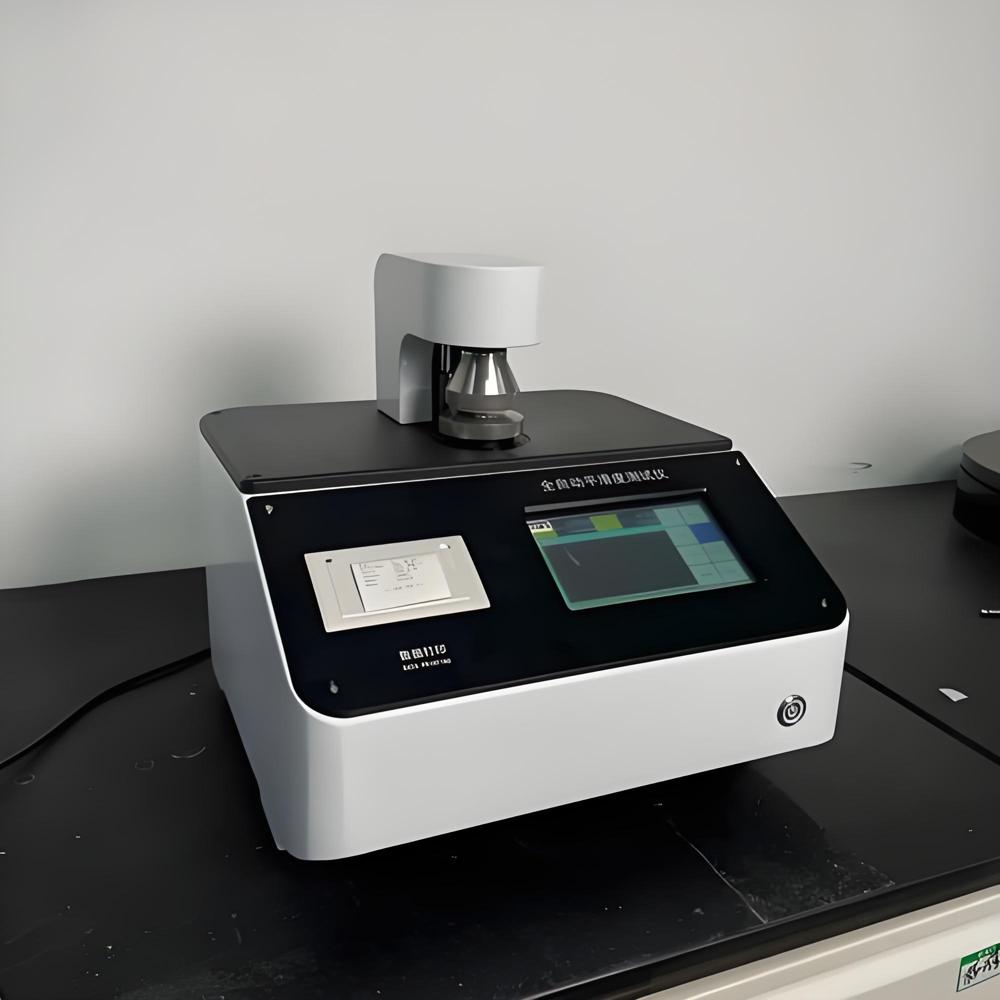

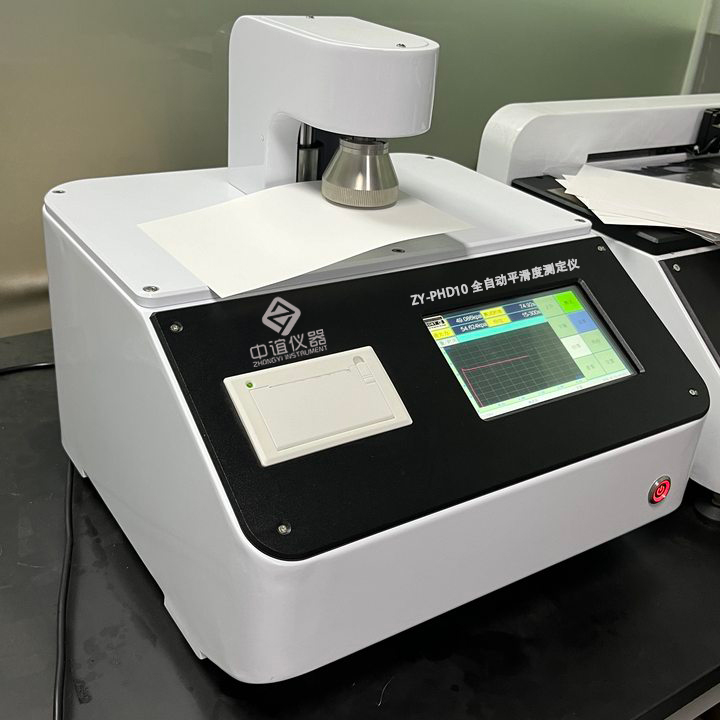

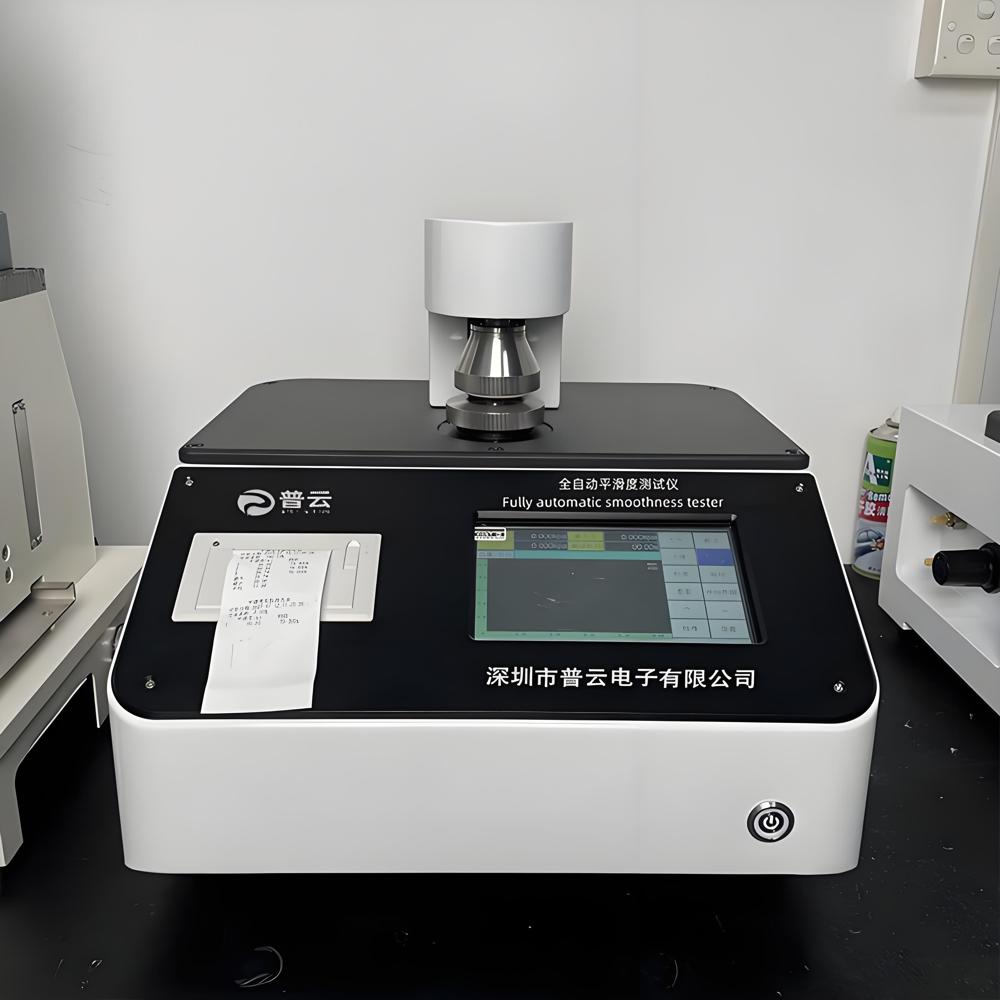

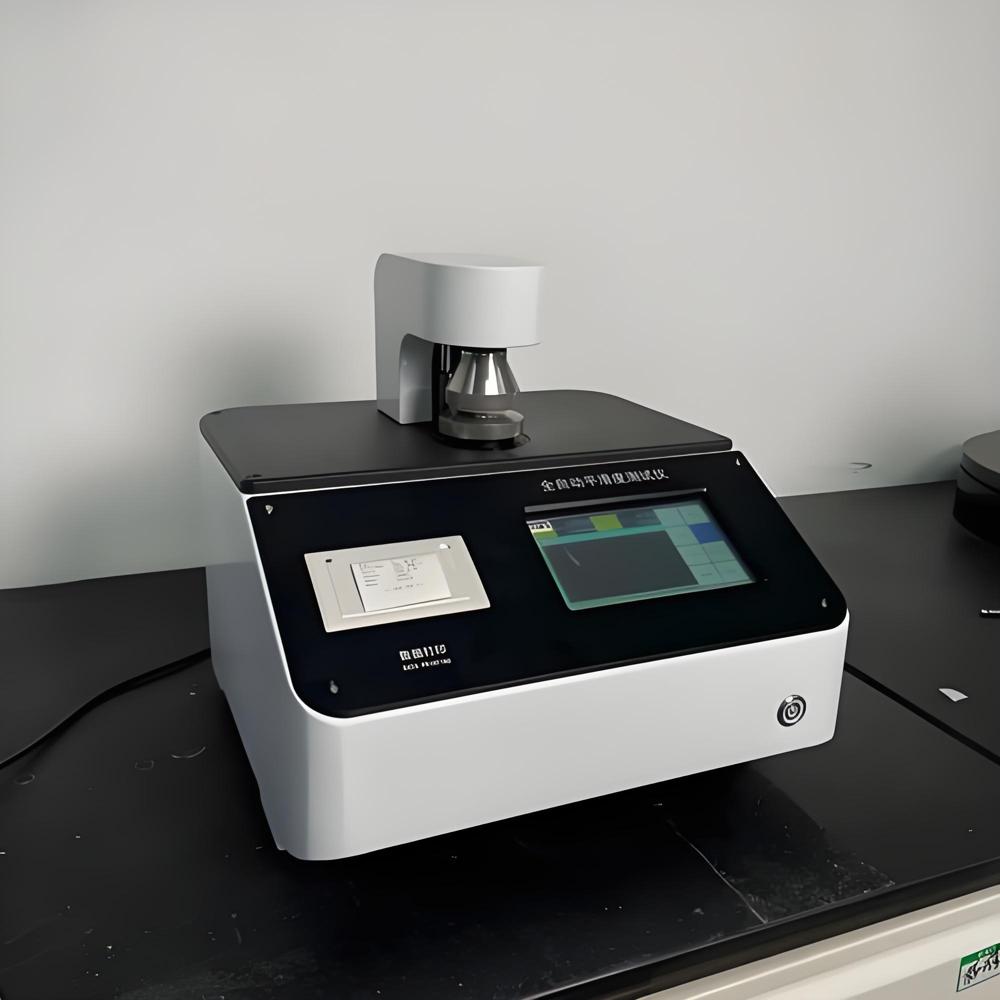

Fully Automatic Digital Smoothness Tester - Real-Time Data Logging & Customizable Reports

138005.0 INR/Unit

Product Details:

- Measuring Range 0.1500 Smoothness units

- Response Time <2 seconds

- Power Supply 220V AC, 50 Hz

- Operating Voltage 220V AC 10%

- Mounting Type Benchtop

- Frequency 50 Hz

- Application Measurement of surface smoothness of paper, board, films

- Click to view more

X

Fully Automatic Digital Smoothness Tester - Real-Time Data Logging & Customizable Reports Price And Quantity

- 138005.0 INR/Unit

- 1 Unit

- Low-maintenance, standard pneumatic fittings

- Reminders programmable (30/60/90 days)

- Internal memory up to 10,000 records

- Pneumatic automatic clamping

- Multi-Language (English, Hindi, Custom)

- <65 dBA

- Multi-user with password protection

- ISO 8791, TAPPI T538

- PDF/CSV/Customisable templates

- Audio-visual alerts for test completion & errors

- Remote diagnostics, on-site installation

Fully Automatic Digital Smoothness Tester - Real-Time Data Logging & Customizable Reports Product Specifications

- 7 Colour Touch Display

- Standard 6 mm pneumatic connector

- Digital Smoothness Tester

- 350 mm

- USB, RS232, WiFi

- Standard 2 mm/sec (adjustable)

- Real-time data logging, customizable reports, user authentication, calibration alerts

- 50 mm x 70 mm

- Up to 50 mm

- 0.01 unit

- 20%80% RH (non-condensing)

- For Laboratory and Industrial Quality Control

- Case: Mild Steel; Surface: Anti-scratch paint

- Fully Automatic

- 10C40C operating range

- Fully Automatic Digital with Touchscreen

- Range 12 Bar (Supplied by external source)

- Approx. 40 kg

- 1% of reading

- 0500 Smoothness units

- Single or multiple (configurable)

- Measurement of surface smoothness of paper, board, films

- 50 Hz

- Benchtop

- 220V AC 10%

- 220V AC, 50 Hz

- <2 seconds

- Up to 100 tests per batch

- 0.1500 Smoothness units

- 020 mm (adjustable)

- Low-maintenance, standard pneumatic fittings

- Reminders programmable (30/60/90 days)

- Internal memory up to 10,000 records

- Pneumatic automatic clamping

- Multi-Language (English, Hindi, Custom)

- <65 dBA

- Multi-user with password protection

- ISO 8791, TAPPI T538

- PDF/CSV/Customisable templates

- Audio-visual alerts for test completion & errors

- Remote diagnostics, on-site installation

Fully Automatic Digital Smoothness Tester - Real-Time Data Logging & Customizable Reports Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

Buick smoothness tester is a high-precision testing equipment designed and developed according to the working principle of the internationally used Buick smoothness tester for testing the surface smoothness performance of paper and cardboard. Smoothness is an important indicator to measure the flatness and finish of the paper surface; It determines the smoothness of a material by passing a certain amount of air through the gap between the surface of the specimen and the glass anvil of the instrument under specific pressure conditions, and measuring the time it takes for air to pass through.How it works:

Smoothness is an index to evaluate the unevenness of the paper surface, which indicates the flatness and smoothness of the paper surface. Paper or cardboard tray material is placed on a glass plate, a specific pressure is applied to create a semi-vacuum, which draws in air and passes it through the contact surface, measuring the time it takes for the vacuum level to change within a specified range. Under a specific state and a certain vacuum degree, the time required for a certain volume of air to pass through the gap between the sample surface and the glass surface under a certain pressure is the smoothness of the paper, which is often expressed in seconds (s). The smoother the surface of the paper, the longer the air will flow in; Conversely, the smoothness is low, and the time for air to flow in is shorter.

Smoothness is an index to evaluate the unevenness of the paper surface, which indicates the flatness and smoothness of the paper surface. Paper or cardboard tray material is placed on a glass plate, a specific pressure is applied to create a semi-vacuum, which draws in air and passes it through the contact surface, measuring the time it takes for the vacuum level to change within a specified range. Under a specific state and a certain vacuum degree, the time required for a certain volume of air to pass through the gap between the sample surface and the glass surface under a certain pressure is the smoothness of the paper, which is often expressed in seconds (s). The smoother the surface of the paper, the longer the air will flow in; Conversely, the smoothness is low, and the time for air to flow in is shorter.

Technical Parameters:

Power supply voltage: AC220V10% 50Hz (AC110V10% 60Hz customized)

Working environment: temperature (10~35)C, relative humidity 85%

Display: dot matrix 7 inch color touch screen

Test area: 100.05 cm

Measuring range: (1~9999)s, divided into (1~15)s, (15~300)s, (300~9999)s and automatic (no more than 200s)

Pressure: 1002 kPa

Timing error: 1s (timing 1000s)

Printing: Thermal printer

Communication interface: RS232

Vacuum setting range (kPa) :

I. File 50.66~48.00

II. File 50.66~48.00

III. File 50.66~29.33

Test method: positive/negative test, difference between two sides

Dimensions: 370330390 mm

Net weight of the instrument: about 29kg

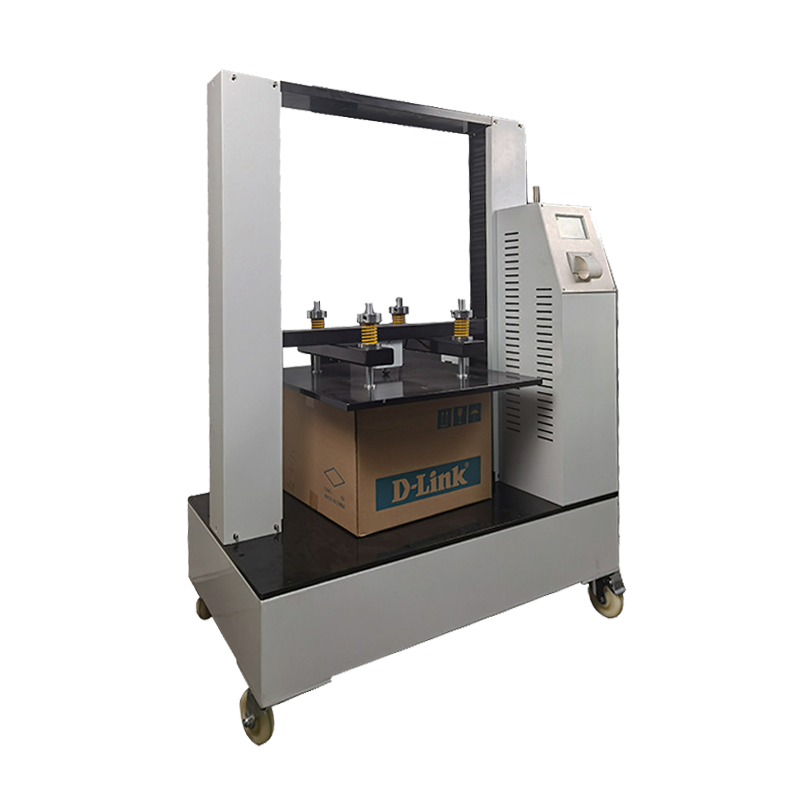

Application field of automatic smoothness tester

1. Paper: paper product packaging and printing smoothness test

2. Paper tray: paper tray packaging box smoothness test

3. Gray cardboard: smoothness test of various gray cardboard, cardboard and composite cardboard

4. Cardboard: Smoothness test of cow cardboard, white card, and whiteboard paper

5. Packaging box: color box, cig ar-ette box, packaging box smoothness test

6. Other materials: smoothness test of other industrial paper that needs to be processed

1. Paper: paper product packaging and printing smoothness test

2. Paper tray: paper tray packaging box smoothness test

3. Gray cardboard: smoothness test of various gray cardboard, cardboard and composite cardboard

4. Cardboard: Smoothness test of cow cardboard, white card, and whiteboard paper

5. Packaging box: color box, cig ar-ette box, packaging box smoothness test

6. Other materials: smoothness test of other industrial paper that needs to be processed

Advanced Data Management and Reporting

With robust internal storage for up to 10,000 records, this tester enables comprehensive data logging and review. Users can generate reports in PDF, CSV, or custom formats, ensuring seamless integration into existing workflows and records management systems. Multi-language support accommodates diverse teams, enhancing operational efficiency in global or multilingual environments.

User-Friendly Automation and Control

The smoothness tester features a fully automatic digital control system with a 7-inch color touchscreen for intuitive operation. Automated pneumatic clamping, user authentication, and audio-visual alerts streamline the testing process. Adjustable test parameters and programmable calibration intervals ensure tailored and reliable measurements for various material specifications.

Reliable Performance and Compliance

Engineered for precision, the device offers a measuring range of 0.1-500 smoothness units with 1% accuracy and 0.01 units resolution. Compliant with ISO 8791 and TAPPI T538 standards, it delivers trustworthy results for industries requiring high-quality surface analysis. The casing's anti-scratch finish and mild steel build ensure durability for demanding laboratory and industrial usage.

FAQ's of Fully Automatic Digital Smoothness Tester - Real-Time Data Logging & Customizable Reports:

Q: How does the Fully Automatic Digital Smoothness Tester enhance laboratory and industrial quality control?

A: This tester streamlines the smoothness measurement process through fully automatic operation, real-time data logging, and customizable reporting. With accurate, repeatable results and multi-user access, it minimizes manual intervention, reduces the risk of error, and meets relevant industry standards, significantly boosting productivity in quality control workflows.Q: What process is followed to test the surface smoothness of paper and similar materials with this device?

A: The operator places the specimen in the pneumatic automatic clamp, selects the test parameters via the touchscreen, and initiates the test. The device then measures surface smoothness at adjustable speed and stroke, logs the data, and provides instant results and alarms for completion or errors. Reports are available in various digital formats.Q: Where can the digital smoothness tester be installed and what are the ideal operating conditions?

A: This benchtop device is suitable for laboratories and industrial quality control setups. It functions optimally at temperatures between 10C-40C and humidity levels from 20%-80% RH (non-condensing), with an ambient noise level below 65 dBA. On-site installation and remote diagnostics support are provided by the manufacturer.Q: When should calibration and maintenance of the tester be performed?

A: Calibration intervals are programmable and the system issues reminders at 30, 60, or 90 days, based on user preference. The design utilizes standard pneumatic fittings for minimal maintenance, helping to ensure long-term precision and reliability with little downtime.Q: How does the tester handle multiple users and data security?

A: It features a multi-user system with password protection, allowing different access levels for various personnel. This safeguards data integrity and restricts unauthorized access to device operations and stored records.Q: What connectivity and integration options are available for data transfer?

A: The device supports multiple interface types including USB, RS232, and WiFi, facilitating easy integration with laboratory information management systems (LIMS) or other data platforms. Reports can be exported in PDF, CSV, or customized templates as needed.Q: What are the key benefits of using this equipment for surface smoothness measurement?

A: Key benefits include high accuracy (1%), reliable automation, rapid response (<2 seconds), versatile specimen capacity, customizable results, secure data handling, and compliance with international standards. Its user-friendly interface, low maintenance requirements, and comprehensive support together offer significant advantages for efficient laboratory and industrial processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese